Consulting

Unlocking locked reserves, drilling un-drillables, and predicting un-predictables, Saving millions of dollars for your assets

PETROLERN Consulting offers a wide range of consulting services in subsurface engineering and geosciences subjects for geothermal, carbon storage, and oil and gas projects. We work closely with our clients’ teams to ensure that the scope of work is fully understood, and our results are properly communicated to them. Our policy is to openly discuss caveats involved in our study and uncertainties in the results with our clients. Our experienced and creative team is ready to provide innovative solutions to any challenging problems concerning:

- We start our consulting projects with a free training course

- We work closely with our clients to ensure knowledge exchange

- Our goal is full satisfaction of our clients

- Quality is what we aim at

- We enjoy challenging and nerve-racking projects

Geothermal Energy:

We care for clean energy as we do for fossil energy

To maximize the sustainability of Geothermal Reservoirs, both Low Temperature and Enhanced Geothermal Systems (EGS), and ensure safe and cost-effective subsurface operations such as drilling, completion, stimulation and injection, knowledge of subsurface state of stress, rock properties, natural fractures, temperature and heat flow is essential. We strive to make the most reliable estimations of these parameters using advanced analytical and numerical models in combination with signal processing and machine learning techniques. PETROLERN is partnered with the University of Utah to leverage its experimental research capabilities and gain access to the Utah FORGE underground field laboratory in Milford for testing developments in EGS technologies.

More information to be provided soon.

More information to be provided soon.

More information to be provided soon.

Carbon Storage:

Environment safety is our red line

Long-term CO2 Storage in geologic formations is a response to growing concerns about climate change resulting from increased carbon dioxide concentrations in the atmosphere. The key to the effective injection of CO2 into the subsurface formations, including depleted oil and gas reservoirs for EOR, is a detailed characterization of the formation properties, in-situ stresses, natural fractures network, seal capacity of cap rock and formation pressure. This is our expertise at PETROLERN. Monitoring, Verification, and Accounting (MVA) to confirm permanent storage of CO2 in geological formations is a significant cost component of any carbon storage campaign and necessary to its success. PETROLERN is researching automated and low-cost MVA solutions to progress carbon storage towards commercialization by providing a reliable and real-time control option over the reservoir as well as reducing the associated costs.

More information to be provided soon.

More information to be provided soon.

More information to be provided soon.

Unconventional Resources:

We believe production from unconventional resources requires unconventional thinking

The remarkable growth of Unconventional Resources in North America has already changed the global energy landscape. Outside of North America, significant volumes of unconventional resources provide an impressive boost in the energy supply of any country that is ready to meet the significant challenges to develop them. At PETROLERN, we pay special attention to the optimized development of unconventional resources. We are proud of its efficient contribution to the development of the shale gas and tight gas resources in the UK and Pakistan. After completing an extensive experimental study on the Vaca Muerta shale, PETROLERN has gained adequate knowledge to help operators in Argentina to develop their shale assets more efficiently and economically.

More information to be provided soon.

More information to be provided soon.

More information to be provided soon.

More information to be provided soon.

Conventional Oil and Gas:

Easy projects are for experts, we are geeks

Drilling and production from Deep-water and HPHT fields are the most challenging operations in the conventional oil and gas industry. Due to significantly higher pressure and temperature and narrow mud weight window, safe drilling, completion and production from these resources require advanced knowledge of subsurface and cutting-edge technologies. PETROLERN’s personnel have extensive experience in modeling and design for deep-water and HPHT operations in Golf of Mexico, North Sea, Off-shore Africa, Pakistan and Caspian Sea.

Our Technical Disciplines

Geoscience Group

- Play Fairway Analysis

- Geomodelling

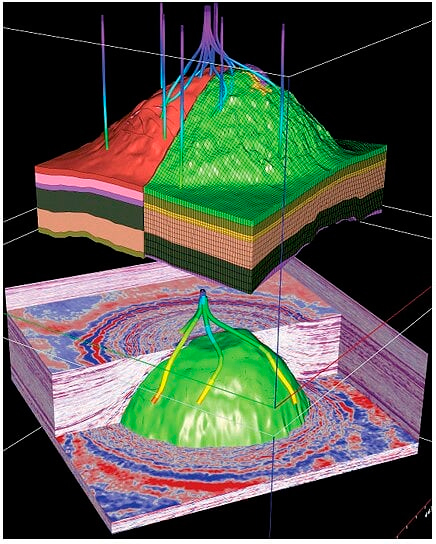

- Geophysics and Seismic Interpretation

- Microseismics Analysis

- Fiber Optic Data Processing

Geoengineering Group

- Subsurface Characterization

- Geomechanical Modeling

- Pore Pressure Prediction

- Wellbore Stability and Drilling Optimization

- Sand Production Prediction and Management

- Hydraulic and Acid Fracturing Modeling and Design

- Well, Casing and Completions Design

- Rock Mechanics Testing Design, Analysis and Interpretation

- Frac Fluid Selection and Sourcing

- Subsurface Monitoring and Visualization

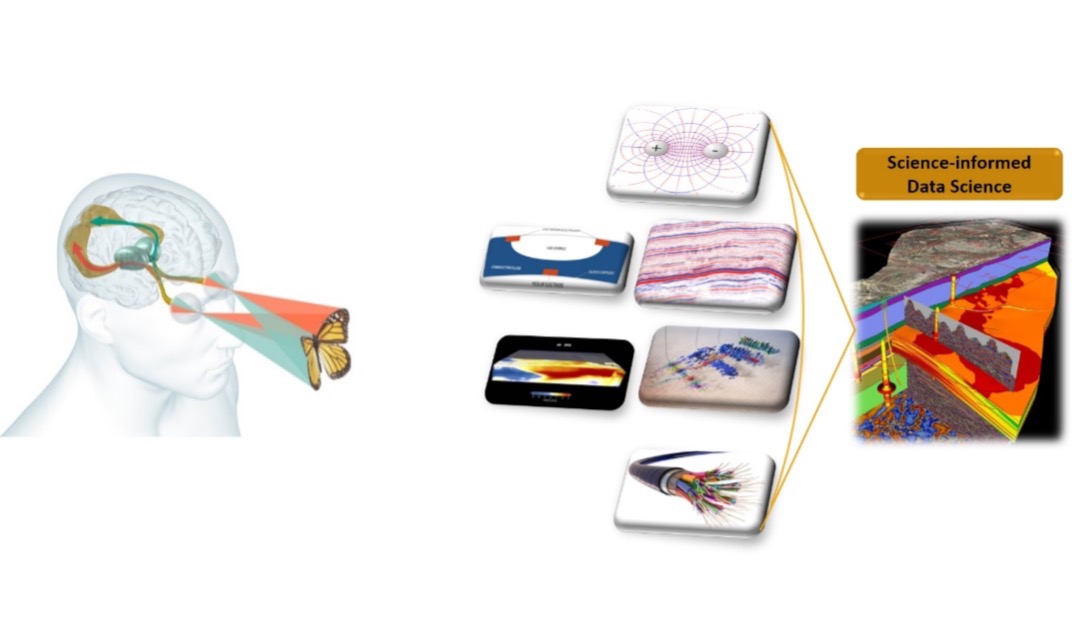

Digital Innovation Group

- Artificial Intelligence

- Subsurface Monitoring

- Data Compression and Processing

- Signal Processing

- Data Management

- Edge Computing

- Software Development

Geoengineering Group

We aim at no subsurface risks

PETROLERN is specialized in Geomechanics with applications in exploration, drilling, reservoir, completions, and production engineering. Our world-class, experienced team provides 1 to 4-D geomechanical modeling, pore pressure prediction, in-situ stress estimation, rock property

evaluation, rock mechanics testing program, wellbore stability analysis, sand production prediction, naturally fractured reservoir characterization, production optimization, hydraulic/acid fracturing modeling and design, gas/fluid injection, well and completion design, casing design, drilling optimization, and well intervention. We also design, execute, supervise and quality control rock mechanics testing programs to make sure that the maximum value is obtained from your expensive core samples.

Our subsurface geoengineering services are provided to all subsurface activities including geothermal, carbon storage and oil and gas operations. We believe that geomechanics is a powerful tool, if used properly, to maximize production, minimize risk and reduce time and cost. We do geomechanics properly and we are proud of saving millions of dollars and hundreds of operating days for our clients.

More information to be provided soon.

Major Projects Include:

- Bowland Shale Gas, UK

- Vaca Muerta Shale, Argentina

- Naushahro Feroze Field, Pakistan

- Gambat Field, Pakistan

- Thang Long Field, Vietnam

- Vibe-1 Well, Denmark

- Preston New Road, UK

- Lynch Block, Midland

- Lynch Block, Midland

- Kandhkot Field, Pakistan

- Hejre HPHT Field, Denmark

- Siri, Nini, Cecile Fields, Denmark

- Mjolner Field, Norway

- Syde Arne Chalk Field, Denmark

- Adhi Field, Pakistan

- Barnett Shale, Texas

- Thebe Field, NW Shelf Australia

- Massa Field, Brazil

- West Qurna, Iraq

- Urdaneta Field, Venezuela

- Bachaquero Field, Venezuela

- Adorf Field, Germany

Digital Innovation Group

Adapting powerful tools from other disciplines is our power.

PETROLERN’s Digital Innovation Group has developed multiple technologies and methodologies related to subsurface operations including:

- Naturally Fractured Zone Identification

- Borehole Enlargement Zone Identification

- Rock Properties Estimation from Basic Logs

- Completion Design Optimization

- Type Curve Clustering

- Drilling Parameters and Bit Selection Optimization

- Hydraulic Fracturing Chemical Optimization

- Screen-out prediction

- Production forecasting

- Synthetic log creation

- Anomaly detection

- Bit failure prediction

- Liquid loading prediction and real time application

Our Success Stories

We strive to turn all our projects into success stories

Drilling in the Bowland Shale, UK

Drilling in Lancashire, UK, for shale gas exploration and appraisal was a disaster with numerous unpredicted drilling problems and non-productive time. The first hydraulic fracturing operation to test the Bowland Shale prospect resulted in a seismic event of magnitudes ML=2.3 which raised many environmental concerns and postponed the project for almost 6 years. PETROLERN’s comprehensive geomechanical study resulted in smooth and problem-free drilling of an S-shape appraisal well and the first ever horizontal shale gas well in the UK at Preston New Road site. The study also provided optimum frac design based on UK regulations and environmental constrains, resulting in multi-stage hydraulic fracturing with no significant seismic events.

Stimulation of a Tight Reservoir in Pakistan

Attempts to stimulate a partially fractured tight carbonate reservoir in South Pakistan indicated that fracturing without an adequate understanding of the in-situ stresses and rock mechanical properties is a huge risk. These initial attempts included a matrix acidizing job followed by a pulsated proppant fracturing job and, eventually, an acid-fracturing job. Despite this, the resulting production rates were unsustainable. PETROLERN’s geomechanical and fracturing study suggested a combined Proppant Fracturing and Closed Fracture Acidizing approach and resulted in the successful completion of a 10-stage stimulation job in a horizontal open-hole of 1,300 m length. This operation was the first of its kind in Pakistan, having a great impact on prospective tight gas developments in Pakistan.

HPHT Drilling in a North Sea Field

Plan for drilling in a North Sea HPHT field was using expensive MPD technology due to a narrow mud weight window. PETROLERN’s geomechanical study suggested a well and casing design that enabled drilling with conventional methods and reduced the cost remarkedly.

HPHT Drilling in a North Sea Field

Drilling in an HPHT field in the North Sea was associated with costly lost circulation and formation collapse problems. PETROLERN’s wellbore stability study showed that minor modification in the well design significantly reduces the risk of wellbore instability. As a result of this study, the next wells were drilled with minimum drilling problems while saving 3 days when drilling the HPHT reservoir section.

Fracturing of a Tight Sand Reservoir in Vietnam

A feasibility study on a tight sand reservoir in Vietnam evaluated that the planned hydraulic fracturing stimulation would be unpreferable due to the current well and completion designs. A add perforation and acid stimulation strategy was proposed instead with large potential incremental production. The study saved millions of dollars for the clients by preventing an operation which would not have any impact on production.

3D Geomechanical Modeling and Compaction Study on a North Sea Field

3D geomechanical modeling and compaction study on a North Sea field revealed that a planned production strategy could cause severe faults reactivation that could potentially risk the reservoir and caprock integrity. An optimum production strategy was designed along with water injection to secure maximum production from the field with no integrity risk.